ADVANCED

Coatings

Pushing the limits

Manufacturers of coatings have been pushing the limits of material science and chemistry since the first industrial coatings were developed. The protection and aesthetic performance requirements for coatings continue to increase:

- Coatings need to last longer in both external and internal environments

- Transparency no longer means just optical transparency — coatings now need to protect a myriad of electronic transmitters and sensors

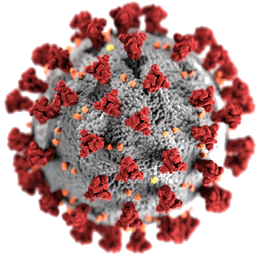

The COVID-19 pandemic brought a new meaning to the term protective coatings. At one time, a coating was there to simply protect the substrate underneath. Today, new active coatings are being applied to commonly touched surfaces to fight viruses and bacteria, helping to reduce the spread of infections.

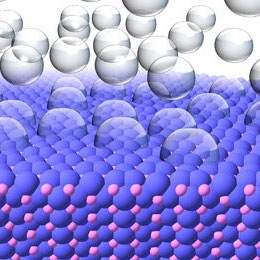

We are seeing increased demand for our nanoparticle technology to act as a functional additive to enhance the performance of existing and new coatings. Our multi-material technology allows us to help coating manufacturers be more efficient in their development by combining properties. A suite of specific nanoparticles can help improve hydrophobicity and abrasion resistance, while also being UV stable and maintaining transparency.

Helping the Coatings market

Some examples of how Promethean Particles helps the coatings market:

- Metal and metal oxide nanoparticles can be added to coatings to improve scratch resistance (such as ZrO2), water repellency (including functionalised SiO2) and antimicrobial properties (such as copper)

- Production in a liquid dispersion allows for straightforward incorporation of particles into coating formulations

- The small particle sizes achieved by our technology — in combination with the reduced risk of particle agglomeration — improve incorporation of the material into coatings to give a smooth finish

- Large-scale solvent transfer equipment enables us to deliver our particles in a wide selection of solvents to meet customer requirements

- Our patented process allows for the production of monodisperse particles in a highly reproducible manner so customers can rely on consistent product quality with every order and production lot

We’re ready to

discuss your next

project

We’re ready to discuss your next project

Have a technical challenge? Connect with our team of experts to see what we can bring to your product application.